High-Quality, Defect-Free

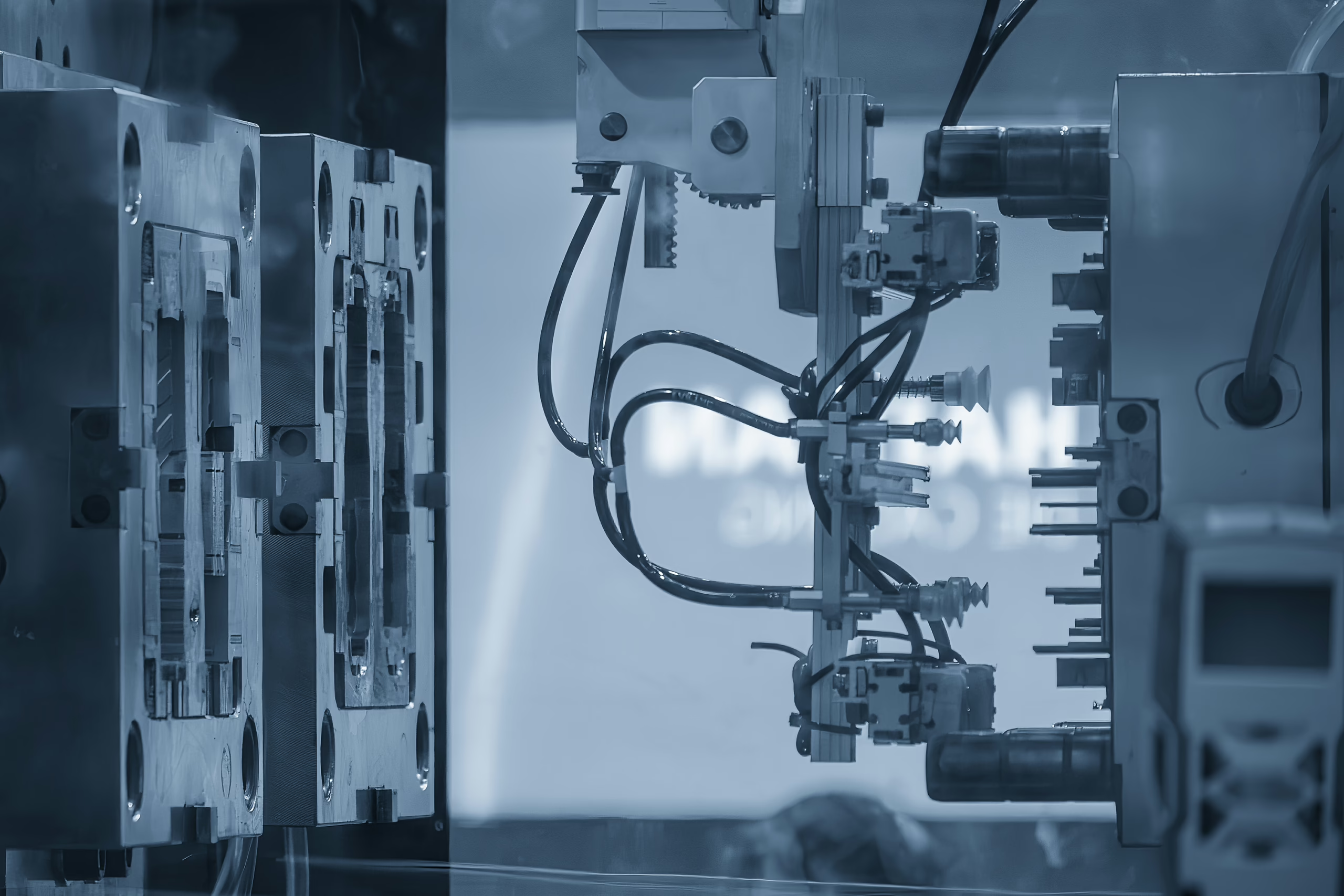

Precision Molding Solutions

Modular Molding International uses rigorous quality control processes and deep PPAP expertise to produce defect-free, high-quality plastic molding parts.

What Makes Modular Molding

International’s Processes Different?

Rigorous quality control standards, meticulous measurements, and thorough testing are essential to ensuring defect-free parts and on-time deliveries. Modular Molding International performs comprehensive inspections at every stage of the product development journey, from verifying incoming materials to final ejections. Our quality inspections are backed by our highly trained plastic molding specialists, advanced digital equipment, Production Part Approval Process (PPAP) expertise, and ISO 9001:2015 certification. This ensures complete perfection of every part we produce and deliver.

Since 1996, MMI has strived to meet and exceed our customers’ expectations. As tolerances become more demanding and parts more complex, we continue delivering best-in-class products thanks to our industry-leading quality control processes and standards. MMI is fully certified and compliant with ISO 9001:2015, guaranteeing parts of the highest level of performance and aesthetic appeal that align with global regulatory standards.

For customers in high-demand industries, our PPAP expertise provides a reliable way to ensure that the first part off the production line is as perfect as the last. It also enables swift identification and resolution of potential issues before they can scale, keeping production on track without costly delays or rework.

When you partner with us, you’ll receive flawless parts shipped anywhere in the world, every time.

MMI’s Precision

Molding Processes

The ability to produce high-quality, high-performing parts is both an art and a science. Superb attention to detail, deep technical prowess, and industry expertise are key to ensuring small errors don’t cost clients big time.

At MMI, we specialize in the art and science of precision molding. Our comprehensive quality control standards are designed to deliver superior consistency and reliability across all products. Quality control is embedded into every phase of the production process, starting from the initial design and continuing through molding, assembly, and packaging.

Our quality checkpoints are strategically placed throughout the manufacturing lifecycle, ensuring that each product undergoes rigorous inspection at key stages. These checkpoints include in-process inspections, qualifying all incoming raw materials, visual checks, dimensional measurements, and functional testing. Each phase is designed to identify and correct potential defects before they can affect the final product. Our proactive approach and investment in inspection help guarantee maximum reliability and performance for every part produced. Customers will have complete confidence in their orders, regardless of industry.

MMI also integrates defect-prevention strategies into every stage of production. We use advanced technologies like automated vision systems and robotic arms to enhance precision and minimize human error. Our skilled engineers and technicians also monitor processes in real-time to detect any deviations that could impact product quality. With a focus on prevention and detection, our approach ensures the final product matches your exact design specifications and has no imperfections.

By embedding quality control in the fabric of our production, we ensure our parts look and perform exactly how you want them to. We stake our reputation in providing top-tier quality assurance solutions that set our customers up for sustainable success.

Fully ISO Certified and Compliant

An International Organization for Standardization (ISO) 9001:2015 certification means MMI adheres to stringent worldwide quality assurance standards when making our parts. It also establishes a framework for continuous improvement, driving us to evaluate and enhance our processes consistently. This establishes trust and credibility among our clients. They know they can count on us to deliver quality beyond their expectations.

We implement a comprehensive quality management system (QMS) across all levels of our operations. Our ISO certification is not just a one-time achievement but an ongoing commitment to maintaining and improving the processes that define our success. ISO 9001:2015 requires us to assess our procedures continuously, identify potential risks, and execute corrective actions when necessary. This meticulous approach ensures we provide customers with consistently reliable, high-quality, and timely products.

An ISO certification guarantees that our processes are aligned with globally recognized best practices, enhancing our ability to meet and exceed customer expectations. It also ensures MMI’s systems and processes become stronger and more efficient every year, helping us remain leaders in our field.

MMI’s ISO 9001:2015 certification assures our customers that we are committed to quality, reliability, and excellence, creating an unbreakable bond of trust.

Deep Production Part Approval Process (PPAP) Expertise

One of the cornerstones of MMI’s commitment to quality is our expertise in the Production Part Approval Process (PPAP). This 18-step manufacturing inspection process is used in automotive, aerospace, and medical supply chains, where precision and reliability are paramount. PPAP ensures that all production parts MMI creates consistently meet required specifications and quality standards, thereby minimizing the risk of defects and establishing the utmost confidence in customers.

At MMI, we leverage PPAP to verify the design, materials, tooling, processes, and inspection methods used to create each part. This structured approach assures that every part leaving our facility meets the precise requirements of our clients.

Our PPAP expertise includes everything from initial part design reviews to process flow diagrams, control plans, and measurement systems analysis. By vigilantly documenting and validating every production stage, we help streamline the manufacturing process, reduce the risk of non-conformities, and improve the overall efficiency of production runs. This reduces costs, shortens lead times, and enhances overall customer satisfaction.

Quality is a non-negotiable in plastic molding. MMI’s deep knowledge of PPAP helps us consistently achieve the same product quality. That’s why we’ve become one of the most trusted names in the industry.

Our Commitment to Plastic

Molding Excellence

MMI is deeply committed to continuously improving our processes, products, and services. Our dedication to excellence extends beyond compliance with industry standards. It’s a core component of our company culture and a promise to our customers. We invest in the latest technologies, continuously refine our manufacturing processes, and prioritize employee training to ensure that every part we produce is exceptional.

Through state-of-the-art inspection equipment, continuous quality checkpoints, and rigorous protocols, MMI is constantly innovating and evolving to stay at the forefront of the precision plastic injection molding industry. Our clients trust us because we never stop striving for improvement and perfection, and we are committed to always delivering the best results.

Need better, faster, and more cost-effective plastic molding solutions? Contact us today.